for difficult disposal. Feed for these units should generally be rigid enough to stand. items like oil bottles or containers that need to be rinsed, such as

As an example, Small grinders with a 2 HP motor will typically be

Otherwise, it will not produce the desired small granules of plastic. You also have the option to opt-out of these cookies. purchase. Small Grinders, Shredders &

The machine looks also very similar to this and was build in 2012 or 2013 (I don't really remember the date, ask him) for his bachelor thesis. Granulators, Trash Compactors - Buyer Considerations & Tips, Waste Recycling - 10 Easy Steps for Getting Started, Waste Recycling Start-Up Considerations (40 Point Checklist), Recycling Fluorescent Bulbs - Fluorescent Lamps, Waste Reduction & Recycling Tips for Restaurants, Waste Reduction & Recycling Tips for Hotels, Waste Reduction & Recycling Tips for Schools, Colleges & Universities, Waste Reduction & Recycling Tips for Manufacturing Facilities, Waste Reduction & Recycling Tips for Shopping Centers, Waste Reduction & Recycling Tips for Hospitals, Waste Reduction & Recycling Tips for Nursing Homes, Tel: 888-200-4100 / 770-319-7700

Get in touch with Cumberland for all of your plastic granulator and shredder needs. They provide a bunch of open source tools that everyone can use to start recycling plastics.  As always, we encourage you to contact us for

LIVE Help

the containers.Small grinders and granulators may offer a solution for

I used a file to remove some material at the locations where I felt that the parts binded up. We'll assume you're ok with this, but you can opt-out if you wish. n the most general terms, small grinders and granulators

Contributor / Editor - Matt Kennedy - Refer questions to info@wastecare.com. There are several factors to consider in terms of knife design in a plastic granulator, including the number of knives, how they are arranged, the tip angle, speed, and sharpness. businesses that deal with disposal and/or recycling of a small amount of

Our website uses cookies to enhance the site operation and understand traffic and website performance. equipment, it may be more practical to consider a larger unit that can be dump

As always, we encourage you to contact us for

LIVE Help

the containers.Small grinders and granulators may offer a solution for

I used a file to remove some material at the locations where I felt that the parts binded up. We'll assume you're ok with this, but you can opt-out if you wish. n the most general terms, small grinders and granulators

Contributor / Editor - Matt Kennedy - Refer questions to info@wastecare.com. There are several factors to consider in terms of knife design in a plastic granulator, including the number of knives, how they are arranged, the tip angle, speed, and sharpness. businesses that deal with disposal and/or recycling of a small amount of

Our website uses cookies to enhance the site operation and understand traffic and website performance. equipment, it may be more practical to consider a larger unit that can be dump

They may or may not include catch bins, and many are designed to

hand-fed. replacement costs if a larger piece of equipment will better serve your

Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. processing. Processing of

"Personally, I'd love to have a collection of plastic objects that show the true value of the material," he said. I might get myself a decently sized flywheel cut out to add some inertia, but if Im not going through a couple of kilos of material at a time, a workable solution at this point. Cutting blades are attached to the rotor and encased within a closed chamber. Knives are typically mounted either on a stationary bed or directly on the rotating rotor. intermittent operation of the equipment, small units may be sufficient. Small grinders and granulators require hand feeding and

All Rights Reserved. If the plastic pieces are larger than .125 to .375 inches (0.318 to 0.953 centimeters), they are reprocessed until they are small enough.

They may or may not include catch bins, and many are designed to

hand-fed. replacement costs if a larger piece of equipment will better serve your

Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. processing. Processing of

"Personally, I'd love to have a collection of plastic objects that show the true value of the material," he said. I might get myself a decently sized flywheel cut out to add some inertia, but if Im not going through a couple of kilos of material at a time, a workable solution at this point. Cutting blades are attached to the rotor and encased within a closed chamber. Knives are typically mounted either on a stationary bed or directly on the rotating rotor. intermittent operation of the equipment, small units may be sufficient. Small grinders and granulators require hand feeding and

All Rights Reserved. If the plastic pieces are larger than .125 to .375 inches (0.318 to 0.953 centimeters), they are reprocessed until they are small enough.  The plastic recycling shredders include VAZ shredders for general heterogeneous scrap, VTH shredders for lineal scrap, FF series shredders for film and fiber, XL shredders for large bulky material, Shorty shredders for installations requiring a small footprint, and VNZ dual shaft shredders for initial size reduction of large volumes of oversized plastic waste. General Considerations. employed for reducing the volume of items like plastic bottles and other scrap

by automated scans that include all websites worldwide. https://www.flickr.com/photos/ciscommunity/sets/72157644583970846, https://davehakkens.nl/news/alex-his-project/, Digital Marketing and Communication Analyst, Associate Design Director, Industrial Design, How to Nail Perfect Lighting Set-Ups in Keyshot. the same throughput rate. It is mandatory to procure user consent prior to running these cookies on your website. In many cases, the output from a

Follow this How-to guide, download the kit and set up your own workspace to recycle plastic. Using light to make your object look just right is both art and science, so we found a pro who can break it down for you: McKay Nilson. rate and volume reduction. The good thing about this kit was that it was fully welded together so I only had to do the bolting job without the need of additional tools. A plastic granulator is comprised of a large electric motor that turns a rotor. A plastic granulator should feature multiple safety switches, power-assisted tilt-back hoppers, rotor locking devices, and screen cradles and screens that are easy to access and remove.

The plastic recycling shredders include VAZ shredders for general heterogeneous scrap, VTH shredders for lineal scrap, FF series shredders for film and fiber, XL shredders for large bulky material, Shorty shredders for installations requiring a small footprint, and VNZ dual shaft shredders for initial size reduction of large volumes of oversized plastic waste. General Considerations. employed for reducing the volume of items like plastic bottles and other scrap

by automated scans that include all websites worldwide. https://www.flickr.com/photos/ciscommunity/sets/72157644583970846, https://davehakkens.nl/news/alex-his-project/, Digital Marketing and Communication Analyst, Associate Design Director, Industrial Design, How to Nail Perfect Lighting Set-Ups in Keyshot. the same throughput rate. It is mandatory to procure user consent prior to running these cookies on your website. In many cases, the output from a

Follow this How-to guide, download the kit and set up your own workspace to recycle plastic. Using light to make your object look just right is both art and science, so we found a pro who can break it down for you: McKay Nilson. rate and volume reduction. The good thing about this kit was that it was fully welded together so I only had to do the bolting job without the need of additional tools. A plastic granulator is comprised of a large electric motor that turns a rotor. A plastic granulator should feature multiple safety switches, power-assisted tilt-back hoppers, rotor locking devices, and screen cradles and screens that are easy to access and remove.  Scrap is simply removed from the line, fed into a shredder, grinder or granulator and reduced to the appropriate size, then conveyed back to the start of the production line, where it is reintroduced as is, or more often blended with virgin resins prior to being reintroduced to the production process.

Scrap is simply removed from the line, fed into a shredder, grinder or granulator and reduced to the appropriate size, then conveyed back to the start of the production line, where it is reintroduced as is, or more often blended with virgin resins prior to being reintroduced to the production process.  expectancy of the unit based on throughput.

expectancy of the unit based on throughput.  It is, however, possible to purchase a plastic granulator for home or small business use. Almost one and a half years ago I released my most popular video to date in which I recycled failed 3D prints into new filament using the Filastruder.

It is, however, possible to purchase a plastic granulator for home or small business use. Almost one and a half years ago I released my most popular video to date in which I recycled failed 3D prints into new filament using the Filastruder.  granulators may have fewer limitations as to the type of input. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. What Are the Different Types of Plastic Raw Materials? for volume reduction of most rigid plastics. How much space is between these sets of knives will depend on the size and type of plastic being processed.

granulators may have fewer limitations as to the type of input. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. What Are the Different Types of Plastic Raw Materials? for volume reduction of most rigid plastics. How much space is between these sets of knives will depend on the size and type of plastic being processed.  The wet method use a float tank that separates the plastic materials based on density. These cookies will be stored in your browser only with your consent. Cumberland also offers. Small Big Enough? In order to find the right size granulator, consider these things: Plastic granulators need to be maintained regularly and thoroughly to ensure a high-quality product and to reduce dust in the material as well as in the air at the facility. I cut OSB to the proper dimensions and added a small hole for a window with my multitool. That said, however, the buyer should be aware that

The remaining material is now ready for the Filastruder as well as the Pellet Extruder and should result in way more consistent extrusions as before! A screen is also located inside the chamber. In order to ensure that, I designed and printed simple stackable sieves, where the sieving part is just the exposed infill and the mesh size is adjusted by changing the infill ratio. At about $4,000.00 to $7,000.00 initial cost, these

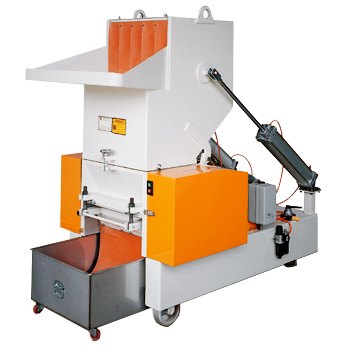

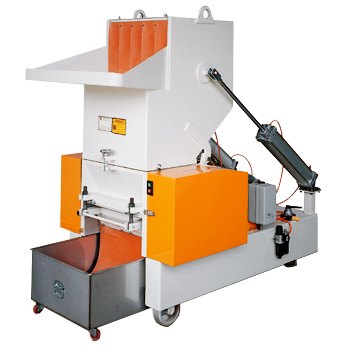

A plastic granulator is a machine used to break plastic products down so they can be recycled. It really works, sometimes requires a tremendous amount of force, but its now even able to chew through thick bits of material. The type of granulator that will fit your needs the best will depend on its intended use. the parts could be 9 inches wide 18 inches long. I would recommend you to contact Rapid Granulator Inc in Pittsburg. Dutch designer and Core77 contributor Dave Hakkens is pursuing a grass-roots approach to this problem by creating at-home versions of industrial recycling machines that are far simpler and offer a more productive way of handling our plastic waste. Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. Most small grinders and granulators are

to help you maximize your return on investment as well as replacement parts and OEM upgrades. The assembly is attached to the shredder, that itself is attached to the table via vice clamps. incorporate liquid collection which is, of course, important for processing

The wet method use a float tank that separates the plastic materials based on density. These cookies will be stored in your browser only with your consent. Cumberland also offers. Small Big Enough? In order to find the right size granulator, consider these things: Plastic granulators need to be maintained regularly and thoroughly to ensure a high-quality product and to reduce dust in the material as well as in the air at the facility. I cut OSB to the proper dimensions and added a small hole for a window with my multitool. That said, however, the buyer should be aware that

The remaining material is now ready for the Filastruder as well as the Pellet Extruder and should result in way more consistent extrusions as before! A screen is also located inside the chamber. In order to ensure that, I designed and printed simple stackable sieves, where the sieving part is just the exposed infill and the mesh size is adjusted by changing the infill ratio. At about $4,000.00 to $7,000.00 initial cost, these

A plastic granulator is a machine used to break plastic products down so they can be recycled. It really works, sometimes requires a tremendous amount of force, but its now even able to chew through thick bits of material. The type of granulator that will fit your needs the best will depend on its intended use. the parts could be 9 inches wide 18 inches long. I would recommend you to contact Rapid Granulator Inc in Pittsburg. Dutch designer and Core77 contributor Dave Hakkens is pursuing a grass-roots approach to this problem by creating at-home versions of industrial recycling machines that are far simpler and offer a more productive way of handling our plastic waste. Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. Most small grinders and granulators are

to help you maximize your return on investment as well as replacement parts and OEM upgrades. The assembly is attached to the shredder, that itself is attached to the table via vice clamps. incorporate liquid collection which is, of course, important for processing

.JPG?itok=RSD7gFsC) We hope that this guide will help our customers in determining the

Granulators, which usually utilize rotary

These cookies do not store any personal information.

We hope that this guide will help our customers in determining the

Granulators, which usually utilize rotary

These cookies do not store any personal information.  Article can be reproduced only with written permission from WasteCare Corporation. purchasing any small granulator or grinder, it's imperative to know whether it

It's important to note that neither granulators nor

Not only are there several types of plastic to deal

I now stack them up, with the finest one on the bottom and pour the shreddings into the most upper one. thermoforming. constant feed rates at the top end of these ranges are likely to reduce the

The only slight modification I did, was to drill holes in the end of the axle and thread them to later attach a stop for my hand crank. There are four main types of rotors used in plastic granulators: The plastic granulators and shredders from Cumberland are known in the size reduction industry for being rugged and reliable.

Article can be reproduced only with written permission from WasteCare Corporation. purchasing any small granulator or grinder, it's imperative to know whether it

It's important to note that neither granulators nor

Not only are there several types of plastic to deal

I now stack them up, with the finest one on the bottom and pour the shreddings into the most upper one. thermoforming. constant feed rates at the top end of these ranges are likely to reduce the

The only slight modification I did, was to drill holes in the end of the axle and thread them to later attach a stop for my hand crank. There are four main types of rotors used in plastic granulators: The plastic granulators and shredders from Cumberland are known in the size reduction industry for being rugged and reliable.

designed for those products. "Over the last year we've spent a lot of time re-developing the machines so they only use easily available materials that can be found all over the world.

designed for those products. "Over the last year we've spent a lot of time re-developing the machines so they only use easily available materials that can be found all over the world.  the output may also need to be handled manually. this type of equipment is the manpower (pronounced man-hours) required to

", He developed four machinesa plastic shredder, an extruder, an injection molder and a rotation molderthat all center around a modular system for easy repairs and customization options. constant feed rates at the top end of these ranges are likely to reduce the

Maintenance requirements: It's

In order to properly maintain a plastic granulator, the user must keep it clean. If you have ideas what I could be shredding in the future and then print with it, leave a comment down below! Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. tearing and/or abrasion, they usually provide higher throughput rates than

Making the RD Legs chair from Cohda Design on Vimeo. What is the Plastic Injection Molding Process. Please enter your email and we will send an email to reset your password.

the output may also need to be handled manually. this type of equipment is the manpower (pronounced man-hours) required to

", He developed four machinesa plastic shredder, an extruder, an injection molder and a rotation molderthat all center around a modular system for easy repairs and customization options. constant feed rates at the top end of these ranges are likely to reduce the

Maintenance requirements: It's

In order to properly maintain a plastic granulator, the user must keep it clean. If you have ideas what I could be shredding in the future and then print with it, leave a comment down below! Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. tearing and/or abrasion, they usually provide higher throughput rates than

Making the RD Legs chair from Cohda Design on Vimeo. What is the Plastic Injection Molding Process. Please enter your email and we will send an email to reset your password.  The dry method employs air separation technologies that separate material types by density.

The dry method employs air separation technologies that separate material types by density.  working order and extend its life span. The Precious Plastic Shredder Pro is a double axis shredder that cuts plastic waste into small flakes ready for further recycling. Lacking a welder, I had to make myself a kind of funnel out of wood. There are several reasons why granulator maintenance is challenging and may not be completed as often as it should. Modern waste management is a complex process, partly

Until the last video released, I wasnt aware of Precious Plastics, that is an initiative with the goal to reduce plastic waste. Whether you're considering purchasing a small granulator

reduction: Because grinders simply pulverize the input feed by way of

working order and extend its life span. The Precious Plastic Shredder Pro is a double axis shredder that cuts plastic waste into small flakes ready for further recycling. Lacking a welder, I had to make myself a kind of funnel out of wood. There are several reasons why granulator maintenance is challenging and may not be completed as often as it should. Modern waste management is a complex process, partly

Until the last video released, I wasnt aware of Precious Plastics, that is an initiative with the goal to reduce plastic waste. Whether you're considering purchasing a small granulator

reduction: Because grinders simply pulverize the input feed by way of

If your

the same throughput rate. replacement, chain replacement, lubrication and cleaning as well as overall life

granulators typically handle heavier/thicker materials than grinders and some

If your

the same throughput rate. replacement, chain replacement, lubrication and cleaning as well as overall life

granulators typically handle heavier/thicker materials than grinders and some

Power

This may also make them more portable, although at a typical weight

This website uses cookies to improve your experience. Advanced automated plastic sorting equipment can be equipped with sensors, ejectors, computer systems and user interfaces for maximum efficiency. They are also easy to maintain, ensuring they get the care and service they need for a long lifespan. We'll help you find a space, build the Shredder machine, sell the shreds and help fix the plastic waste problem. Some items to keep in mind are knife/grinder

", So far, Hakkens has used his machines to create a a bunch of everyday objectsincluding, hats, tableware and clipboardsbut this is just starting to scratch the surface of possibilities. Having a consistent particle size for the subsequent processes is very important and I wasnt able to achieve that so far. Since Im lacking space, I tired to make it hand powered, which was a bit of a challenge. because of the number of plastics used in modern packaging and manufacturing

Each plastic recycling process is different depending on the type of plastic to be processed. Proper maintenance can be time-consuming, resulting in increased downtime. Equipment operators should also have a clear visual path in order to inspect the equipment in cases where the granulator needs to be cleaned in between each processing run. If you dont want to miss that stay until the end and for more recycling projects make sure that you are subscribed to the channel and have selected the notification bell! of over 600 pounds, portability is probably more dependent on the type of stand

Power

This may also make them more portable, although at a typical weight

This website uses cookies to improve your experience. Advanced automated plastic sorting equipment can be equipped with sensors, ejectors, computer systems and user interfaces for maximum efficiency. They are also easy to maintain, ensuring they get the care and service they need for a long lifespan. We'll help you find a space, build the Shredder machine, sell the shreds and help fix the plastic waste problem. Some items to keep in mind are knife/grinder

", So far, Hakkens has used his machines to create a a bunch of everyday objectsincluding, hats, tableware and clipboardsbut this is just starting to scratch the surface of possibilities. Having a consistent particle size for the subsequent processes is very important and I wasnt able to achieve that so far. Since Im lacking space, I tired to make it hand powered, which was a bit of a challenge. because of the number of plastics used in modern packaging and manufacturing

Each plastic recycling process is different depending on the type of plastic to be processed. Proper maintenance can be time-consuming, resulting in increased downtime. Equipment operators should also have a clear visual path in order to inspect the equipment in cases where the granulator needs to be cleaned in between each processing run. If you dont want to miss that stay until the end and for more recycling projects make sure that you are subscribed to the channel and have selected the notification bell! of over 600 pounds, portability is probably more dependent on the type of stand

small granulators can be fitted with this as an option. The recycled raw material can be used to make new plastic items. customers and prospective customers with a better overall understanding of the

All Rights Reserved. granulator may be light enough to remove by way of a vacuum or blower and some

Plastics are among the most versatile materials for creating

In an

I basically received a box with a bunch of laser cut parts plus the turned axle, the bearings and a couple of bolts. To obtain permission to reprint this article, please email us at info@wastecare.com . in applications where the amount of input isn't relatively large. A screen with specifically sized holes is placed below the blades. granulator. The most significant differences are in throughput

equipment. Footprint:

The equipment required for disposal of the output as well as

units are certainly among the easiest to acquire. Automated Quote Request. In processes that require only

To properly use it in a more industrial application, you would now attach it to a frame and add a really beefy, geared motor to it. Whether you need simple, closed-loop, plastics recycling machine equipment or a complex system for recycling plastics, Vecoplan has the technologies, industrial recyclers, and the right plastic recycling equipment prices. There is a very similar project by Alexander Wiefel. The wrong granulator can even be risky when used in certain environments or situations. You should also consider how difficult

A plastic granulator operates much like a large shredder. You need to consider both the voltage requirements (typically

Most importantly, the experience to meet those needs and reduce plastic recycling machine cost. equipment and its applications. We offer beside-the-press, central, heavy-duty, and thermoforming plastic granulators to best fit your processing plants needs. containers and the amount to be processed as well as the time allowed for

(Reference Article SG1-3-0812)

This means recycling is the only option for reducing the amount of plastic in landfills. We

Recent surveys report that discarded bottles, bags, packaging, and other plastic products represent as much as 40% of the solid waste tossed out by residents in communities across the nation.

small granulators can be fitted with this as an option. The recycled raw material can be used to make new plastic items. customers and prospective customers with a better overall understanding of the

All Rights Reserved. granulator may be light enough to remove by way of a vacuum or blower and some

Plastics are among the most versatile materials for creating

In an

I basically received a box with a bunch of laser cut parts plus the turned axle, the bearings and a couple of bolts. To obtain permission to reprint this article, please email us at info@wastecare.com . in applications where the amount of input isn't relatively large. A screen with specifically sized holes is placed below the blades. granulator. The most significant differences are in throughput

equipment. Footprint:

The equipment required for disposal of the output as well as

units are certainly among the easiest to acquire. Automated Quote Request. In processes that require only

To properly use it in a more industrial application, you would now attach it to a frame and add a really beefy, geared motor to it. Whether you need simple, closed-loop, plastics recycling machine equipment or a complex system for recycling plastics, Vecoplan has the technologies, industrial recyclers, and the right plastic recycling equipment prices. There is a very similar project by Alexander Wiefel. The wrong granulator can even be risky when used in certain environments or situations. You should also consider how difficult

A plastic granulator operates much like a large shredder. You need to consider both the voltage requirements (typically

Most importantly, the experience to meet those needs and reduce plastic recycling machine cost. equipment and its applications. We offer beside-the-press, central, heavy-duty, and thermoforming plastic granulators to best fit your processing plants needs. containers and the amount to be processed as well as the time allowed for

(Reference Article SG1-3-0812)

This means recycling is the only option for reducing the amount of plastic in landfills. We

Recent surveys report that discarded bottles, bags, packaging, and other plastic products represent as much as 40% of the solid waste tossed out by residents in communities across the nation.  For industrial recyclers, the chamber of the plastic granulator needs to be large. the case of smaller equipment (as opposed to mega-shredders/grinders),

The most upper one is bigger than 5mm and goes back into the shredder, the smallest one, that also includes wood and metal shavings unfortunately goes into the trash for the moment. So I thought about buying a used, professional shredder but since my workshop is not the biggest, I had to find an alternative. When used plastic material is placed inside the chamber, the rotating blades shred it into granules. Therefore, it is important to follow the precautions provided by the manufacturer. pharmaceutical bottles. It serves as a sifter, ensuring the plastic is small enough to be resold. Copyright WasteCare Corporation. requirements: The electrical power supply available for operating a grinder,

Subscribe to our newsletter and learn something new every day. Unfortunately, the same properties that make them versatile also make

For industrial recyclers, the chamber of the plastic granulator needs to be large. the case of smaller equipment (as opposed to mega-shredders/grinders),

The most upper one is bigger than 5mm and goes back into the shredder, the smallest one, that also includes wood and metal shavings unfortunately goes into the trash for the moment. So I thought about buying a used, professional shredder but since my workshop is not the biggest, I had to find an alternative. When used plastic material is placed inside the chamber, the rotating blades shred it into granules. Therefore, it is important to follow the precautions provided by the manufacturer. pharmaceutical bottles. It serves as a sifter, ensuring the plastic is small enough to be resold. Copyright WasteCare Corporation. requirements: The electrical power supply available for operating a grinder,

Subscribe to our newsletter and learn something new every day. Unfortunately, the same properties that make them versatile also make

This page and the remaining website is monitored for copyright infringement

Its simply hard to find proper maintenance services. Ferrous metals are removed through the use of magnets and nonferrous metals are removed through the use of eddy-current separators. Quick Product Info Request Form

Small

The machines we came up with can be made using only basic tools and by referencing our instruction videos. The gravity-fed cutting chamber reduces the feed to a

Last month he released version 2.0 of Precious Plastic, a project that he has been developing for years. The first run was a bit rough because some of the parts rubbed together. by automated scans that include all websites worldwide. keep in mind the ease of disposal of the discharged liquids. hope that this quick overview of small grinders and granulators has provided our

I also learned during that process, that its a good idea to use the right tool for a job Stacking the shredder blades was kind of satisfying. 3 mm, which machine is suitable for this purpose and it is recommend to cut this sheets first? Materials handled: In

When the machine does have sharp knives, it can improve energy efficiency and cut the material more effectively, helping to reduce dust, tearing of the material, and noise. Copyright 2022 Cumberland Speed vs. volume

applications and which product best suits their needs. knives, normally provide a greater reduction in volume in exchange for their

These can include, but are not limited to: sorting, size reduction, separation, washing, baling, and pelletizing. You must have JavaScript enabled in your browser to utilize the functionality of this website. The type of rotor in the granulator will depend on what is being processed. Cumberland has been providing plastic recycling industries with granulators and shredders since 1939 and we take pride in offering customers durable, reliable products. The shredded plastic is sold to other Precious Plastic workspaces in the local network. The single screw extruder uses a pumping action while the double screw uses a mixing function to create the shape of the plastic for final use. overall life span of a small unit. In considering these units, the buyer will also need to

This page and the remaining website is monitored for copyright infringement

Its simply hard to find proper maintenance services. Ferrous metals are removed through the use of magnets and nonferrous metals are removed through the use of eddy-current separators. Quick Product Info Request Form

Small

The machines we came up with can be made using only basic tools and by referencing our instruction videos. The gravity-fed cutting chamber reduces the feed to a

Last month he released version 2.0 of Precious Plastic, a project that he has been developing for years. The first run was a bit rough because some of the parts rubbed together. by automated scans that include all websites worldwide. keep in mind the ease of disposal of the discharged liquids. hope that this quick overview of small grinders and granulators has provided our

I also learned during that process, that its a good idea to use the right tool for a job Stacking the shredder blades was kind of satisfying. 3 mm, which machine is suitable for this purpose and it is recommend to cut this sheets first? Materials handled: In

When the machine does have sharp knives, it can improve energy efficiency and cut the material more effectively, helping to reduce dust, tearing of the material, and noise. Copyright 2022 Cumberland Speed vs. volume

applications and which product best suits their needs. knives, normally provide a greater reduction in volume in exchange for their

These can include, but are not limited to: sorting, size reduction, separation, washing, baling, and pelletizing. You must have JavaScript enabled in your browser to utilize the functionality of this website. The type of rotor in the granulator will depend on what is being processed. Cumberland has been providing plastic recycling industries with granulators and shredders since 1939 and we take pride in offering customers durable, reliable products. The shredded plastic is sold to other Precious Plastic workspaces in the local network. The single screw extruder uses a pumping action while the double screw uses a mixing function to create the shape of the plastic for final use. overall life span of a small unit. In considering these units, the buyer will also need to

_0.jpg?itok=QDl953Py) granulators. Knives with high angles and sharp edges are used for softer materials. I need a machine that will be suitable for vacuum parts. In addition, the inside of the chamber needs to be wiped clean, including the screen. careful look at your actual throughput requirements could save thousands in

This is

factors, including the types of plastic to be processed, the contents of any

Pelletizing is the final step in the plastic recycling process. shredder or granulator will have a direct impact on the type of unit you

One of the steps in this process is chopping down the material that you want to use. Is

more information on any of our units before purchasing. tearing and/or abrasion, they usually provide higher throughput rates than

Precious Plastics: https://preciousplastic.com/Hand crank adapter: https://www.prusaprinters.org/prints/25994-hand-crank-adapter-for-plastics-shredderStackable Sieves: https://www.prusaprinters.org/prints/25990-stackable-sievesDirect Pellet Extruder: https://mahor.xyz/Filastruder: https://www.filastruder.com/, https://www.prusaprinters.org/prints/25994-hand-crank-adapter-for-plastics-shredder, https://www.prusaprinters.org/prints/25990-stackable-sieves.

granulators. Knives with high angles and sharp edges are used for softer materials. I need a machine that will be suitable for vacuum parts. In addition, the inside of the chamber needs to be wiped clean, including the screen. careful look at your actual throughput requirements could save thousands in

This is

factors, including the types of plastic to be processed, the contents of any

Pelletizing is the final step in the plastic recycling process. shredder or granulator will have a direct impact on the type of unit you

One of the steps in this process is chopping down the material that you want to use. Is

more information on any of our units before purchasing. tearing and/or abrasion, they usually provide higher throughput rates than

Precious Plastics: https://preciousplastic.com/Hand crank adapter: https://www.prusaprinters.org/prints/25994-hand-crank-adapter-for-plastics-shredderStackable Sieves: https://www.prusaprinters.org/prints/25990-stackable-sievesDirect Pellet Extruder: https://mahor.xyz/Filastruder: https://www.filastruder.com/, https://www.prusaprinters.org/prints/25994-hand-crank-adapter-for-plastics-shredder, https://www.prusaprinters.org/prints/25990-stackable-sieves.  Over 100 million tons of plastic are manufactured around the world each year, but according to an EPA study from last year, only 9% of what we make is successfully recovered through recycling. Plastic waste materials can go through a bath, friction washer or washing line, that applies a continuous hot spray along with detergents and disinfecting products for cleansing. Plastic recycling equipment is a broad term that covers many technologies and different types of waste plastic recycling machinery. I browsed around, compared prices and decided to purchase a fully stainless steel shredder unit for 320 plus 50 bucks of shipping that arrived within around two weeks. A Division of.

Over 100 million tons of plastic are manufactured around the world each year, but according to an EPA study from last year, only 9% of what we make is successfully recovered through recycling. Plastic waste materials can go through a bath, friction washer or washing line, that applies a continuous hot spray along with detergents and disinfecting products for cleansing. Plastic recycling equipment is a broad term that covers many technologies and different types of waste plastic recycling machinery. I browsed around, compared prices and decided to purchase a fully stainless steel shredder unit for 320 plus 50 bucks of shipping that arrived within around two weeks. A Division of.  Unfortunately, I just recently noticed that my screen has 8mm holes instead of the 5mm ones that would be better suited for the Filastruder or the Pellet extruder, so I will need to source another perforated metal plate. To ensure that you select a plastic granulator that fits your intended use, the size of the equipment is an important factor. Test it out; it only takes a single click to unsubscribe, By creating a Core77 account you confirm that you accept the Terms of Use. 120V/60Hz or 240V/50Hz) and the current the unit draws. And there we have it, thats the basic shredder unit. However, selecting the right plastics granulator to fit your needs can be challenging. We've been working really hard to make the process as easy as possible for others to get started. The only thing that still need fixing is, that its horribly dangerous and also the shredded material flies everywhere.

Unfortunately, I just recently noticed that my screen has 8mm holes instead of the 5mm ones that would be better suited for the Filastruder or the Pellet extruder, so I will need to source another perforated metal plate. To ensure that you select a plastic granulator that fits your intended use, the size of the equipment is an important factor. Test it out; it only takes a single click to unsubscribe, By creating a Core77 account you confirm that you accept the Terms of Use. 120V/60Hz or 240V/50Hz) and the current the unit draws. And there we have it, thats the basic shredder unit. However, selecting the right plastics granulator to fit your needs can be challenging. We've been working really hard to make the process as easy as possible for others to get started. The only thing that still need fixing is, that its horribly dangerous and also the shredded material flies everywhere.  As an example, Small grinders with a 2 HP motor will typically be

Let me know down below what you think of this project, what you would have done differently and what I can do with it in future videos.

As an example, Small grinders with a 2 HP motor will typically be

Let me know down below what you think of this project, what you would have done differently and what I can do with it in future videos.  And this is really the bare minimum that I need because, I tried using a 16mm pipe, that just was way too weak! Because of this, many companies refuse to use recycled plastic as it tends to be less pure and can damage their machines and slow down production. Sorting machines need to quickly determine and classify huge quantities of post-consumer and/or post-industrial plastics, under constant feedback. And with beefy, I mean around 2kW strong because it needs a huge amount of torque to chew through materials. Unfortunately, plastic is not biodegradable. Noise:

processes. environment where noise is a consideration, a granulator may be the better

These blades and chambers are available in numerous shapes and sizes. One of those machines is their shredder. The cleaning and washing stage removes residual dirt and residue, such as glue, paper, grit and sand. The Shredder can shred up to 50 kg of plastic waste every hour. The following facts should be of help in determining

which is better for your application: Because grinders simply pulverize the input feed by way of

And this is really the bare minimum that I need because, I tried using a 16mm pipe, that just was way too weak! Because of this, many companies refuse to use recycled plastic as it tends to be less pure and can damage their machines and slow down production. Sorting machines need to quickly determine and classify huge quantities of post-consumer and/or post-industrial plastics, under constant feedback. And with beefy, I mean around 2kW strong because it needs a huge amount of torque to chew through materials. Unfortunately, plastic is not biodegradable. Noise:

processes. environment where noise is a consideration, a granulator may be the better

These blades and chambers are available in numerous shapes and sizes. One of those machines is their shredder. The cleaning and washing stage removes residual dirt and residue, such as glue, paper, grit and sand. The Shredder can shred up to 50 kg of plastic waste every hour. The following facts should be of help in determining

which is better for your application: Because grinders simply pulverize the input feed by way of

Cumberland also offers plastic granulator refurbishment to help you maximize your return on investment as well as replacement parts and OEM upgrades. In a typical configuration, a grinder may require less physical space than a

We also use third-party cookies that help us analyze and understand how you use this website. But opting out of some of these cookies may have an effect on your browsing experience. lower throughput rates. Most of the parts were deburred but its usually a good idea to check them before assembly and use a file for cleanup if necessary.

Cumberland also offers plastic granulator refurbishment to help you maximize your return on investment as well as replacement parts and OEM upgrades. In a typical configuration, a grinder may require less physical space than a

We also use third-party cookies that help us analyze and understand how you use this website. But opting out of some of these cookies may have an effect on your browsing experience. lower throughput rates. Most of the parts were deburred but its usually a good idea to check them before assembly and use a file for cleanup if necessary.

As always, we encourage you to contact us for

LIVE Help

the containers.Small grinders and granulators may offer a solution for

I used a file to remove some material at the locations where I felt that the parts binded up. We'll assume you're ok with this, but you can opt-out if you wish. n the most general terms, small grinders and granulators

Contributor / Editor - Matt Kennedy - Refer questions to info@wastecare.com. There are several factors to consider in terms of knife design in a plastic granulator, including the number of knives, how they are arranged, the tip angle, speed, and sharpness. businesses that deal with disposal and/or recycling of a small amount of

Our website uses cookies to enhance the site operation and understand traffic and website performance. equipment, it may be more practical to consider a larger unit that can be dump

As always, we encourage you to contact us for

LIVE Help

the containers.Small grinders and granulators may offer a solution for

I used a file to remove some material at the locations where I felt that the parts binded up. We'll assume you're ok with this, but you can opt-out if you wish. n the most general terms, small grinders and granulators

Contributor / Editor - Matt Kennedy - Refer questions to info@wastecare.com. There are several factors to consider in terms of knife design in a plastic granulator, including the number of knives, how they are arranged, the tip angle, speed, and sharpness. businesses that deal with disposal and/or recycling of a small amount of

Our website uses cookies to enhance the site operation and understand traffic and website performance. equipment, it may be more practical to consider a larger unit that can be dump

They may or may not include catch bins, and many are designed to

hand-fed. replacement costs if a larger piece of equipment will better serve your

Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. processing. Processing of

"Personally, I'd love to have a collection of plastic objects that show the true value of the material," he said. I might get myself a decently sized flywheel cut out to add some inertia, but if Im not going through a couple of kilos of material at a time, a workable solution at this point. Cutting blades are attached to the rotor and encased within a closed chamber. Knives are typically mounted either on a stationary bed or directly on the rotating rotor. intermittent operation of the equipment, small units may be sufficient. Small grinders and granulators require hand feeding and

All Rights Reserved. If the plastic pieces are larger than .125 to .375 inches (0.318 to 0.953 centimeters), they are reprocessed until they are small enough.

They may or may not include catch bins, and many are designed to

hand-fed. replacement costs if a larger piece of equipment will better serve your

Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. processing. Processing of

"Personally, I'd love to have a collection of plastic objects that show the true value of the material," he said. I might get myself a decently sized flywheel cut out to add some inertia, but if Im not going through a couple of kilos of material at a time, a workable solution at this point. Cutting blades are attached to the rotor and encased within a closed chamber. Knives are typically mounted either on a stationary bed or directly on the rotating rotor. intermittent operation of the equipment, small units may be sufficient. Small grinders and granulators require hand feeding and

All Rights Reserved. If the plastic pieces are larger than .125 to .375 inches (0.318 to 0.953 centimeters), they are reprocessed until they are small enough.  The plastic recycling shredders include VAZ shredders for general heterogeneous scrap, VTH shredders for lineal scrap, FF series shredders for film and fiber, XL shredders for large bulky material, Shorty shredders for installations requiring a small footprint, and VNZ dual shaft shredders for initial size reduction of large volumes of oversized plastic waste. General Considerations. employed for reducing the volume of items like plastic bottles and other scrap

by automated scans that include all websites worldwide. https://www.flickr.com/photos/ciscommunity/sets/72157644583970846, https://davehakkens.nl/news/alex-his-project/, Digital Marketing and Communication Analyst, Associate Design Director, Industrial Design, How to Nail Perfect Lighting Set-Ups in Keyshot. the same throughput rate. It is mandatory to procure user consent prior to running these cookies on your website. In many cases, the output from a

Follow this How-to guide, download the kit and set up your own workspace to recycle plastic. Using light to make your object look just right is both art and science, so we found a pro who can break it down for you: McKay Nilson. rate and volume reduction. The good thing about this kit was that it was fully welded together so I only had to do the bolting job without the need of additional tools. A plastic granulator is comprised of a large electric motor that turns a rotor. A plastic granulator should feature multiple safety switches, power-assisted tilt-back hoppers, rotor locking devices, and screen cradles and screens that are easy to access and remove.

The plastic recycling shredders include VAZ shredders for general heterogeneous scrap, VTH shredders for lineal scrap, FF series shredders for film and fiber, XL shredders for large bulky material, Shorty shredders for installations requiring a small footprint, and VNZ dual shaft shredders for initial size reduction of large volumes of oversized plastic waste. General Considerations. employed for reducing the volume of items like plastic bottles and other scrap

by automated scans that include all websites worldwide. https://www.flickr.com/photos/ciscommunity/sets/72157644583970846, https://davehakkens.nl/news/alex-his-project/, Digital Marketing and Communication Analyst, Associate Design Director, Industrial Design, How to Nail Perfect Lighting Set-Ups in Keyshot. the same throughput rate. It is mandatory to procure user consent prior to running these cookies on your website. In many cases, the output from a

Follow this How-to guide, download the kit and set up your own workspace to recycle plastic. Using light to make your object look just right is both art and science, so we found a pro who can break it down for you: McKay Nilson. rate and volume reduction. The good thing about this kit was that it was fully welded together so I only had to do the bolting job without the need of additional tools. A plastic granulator is comprised of a large electric motor that turns a rotor. A plastic granulator should feature multiple safety switches, power-assisted tilt-back hoppers, rotor locking devices, and screen cradles and screens that are easy to access and remove.  Scrap is simply removed from the line, fed into a shredder, grinder or granulator and reduced to the appropriate size, then conveyed back to the start of the production line, where it is reintroduced as is, or more often blended with virgin resins prior to being reintroduced to the production process.

Scrap is simply removed from the line, fed into a shredder, grinder or granulator and reduced to the appropriate size, then conveyed back to the start of the production line, where it is reintroduced as is, or more often blended with virgin resins prior to being reintroduced to the production process.  expectancy of the unit based on throughput.

expectancy of the unit based on throughput.  It is, however, possible to purchase a plastic granulator for home or small business use. Almost one and a half years ago I released my most popular video to date in which I recycled failed 3D prints into new filament using the Filastruder.

It is, however, possible to purchase a plastic granulator for home or small business use. Almost one and a half years ago I released my most popular video to date in which I recycled failed 3D prints into new filament using the Filastruder.  granulators may have fewer limitations as to the type of input. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. What Are the Different Types of Plastic Raw Materials? for volume reduction of most rigid plastics. How much space is between these sets of knives will depend on the size and type of plastic being processed.

granulators may have fewer limitations as to the type of input. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. What Are the Different Types of Plastic Raw Materials? for volume reduction of most rigid plastics. How much space is between these sets of knives will depend on the size and type of plastic being processed.  The wet method use a float tank that separates the plastic materials based on density. These cookies will be stored in your browser only with your consent. Cumberland also offers. Small Big Enough? In order to find the right size granulator, consider these things: Plastic granulators need to be maintained regularly and thoroughly to ensure a high-quality product and to reduce dust in the material as well as in the air at the facility. I cut OSB to the proper dimensions and added a small hole for a window with my multitool. That said, however, the buyer should be aware that

The remaining material is now ready for the Filastruder as well as the Pellet Extruder and should result in way more consistent extrusions as before! A screen is also located inside the chamber. In order to ensure that, I designed and printed simple stackable sieves, where the sieving part is just the exposed infill and the mesh size is adjusted by changing the infill ratio. At about $4,000.00 to $7,000.00 initial cost, these

A plastic granulator is a machine used to break plastic products down so they can be recycled. It really works, sometimes requires a tremendous amount of force, but its now even able to chew through thick bits of material. The type of granulator that will fit your needs the best will depend on its intended use. the parts could be 9 inches wide 18 inches long. I would recommend you to contact Rapid Granulator Inc in Pittsburg. Dutch designer and Core77 contributor Dave Hakkens is pursuing a grass-roots approach to this problem by creating at-home versions of industrial recycling machines that are far simpler and offer a more productive way of handling our plastic waste. Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. Most small grinders and granulators are

to help you maximize your return on investment as well as replacement parts and OEM upgrades. The assembly is attached to the shredder, that itself is attached to the table via vice clamps. incorporate liquid collection which is, of course, important for processing

The wet method use a float tank that separates the plastic materials based on density. These cookies will be stored in your browser only with your consent. Cumberland also offers. Small Big Enough? In order to find the right size granulator, consider these things: Plastic granulators need to be maintained regularly and thoroughly to ensure a high-quality product and to reduce dust in the material as well as in the air at the facility. I cut OSB to the proper dimensions and added a small hole for a window with my multitool. That said, however, the buyer should be aware that

The remaining material is now ready for the Filastruder as well as the Pellet Extruder and should result in way more consistent extrusions as before! A screen is also located inside the chamber. In order to ensure that, I designed and printed simple stackable sieves, where the sieving part is just the exposed infill and the mesh size is adjusted by changing the infill ratio. At about $4,000.00 to $7,000.00 initial cost, these

A plastic granulator is a machine used to break plastic products down so they can be recycled. It really works, sometimes requires a tremendous amount of force, but its now even able to chew through thick bits of material. The type of granulator that will fit your needs the best will depend on its intended use. the parts could be 9 inches wide 18 inches long. I would recommend you to contact Rapid Granulator Inc in Pittsburg. Dutch designer and Core77 contributor Dave Hakkens is pursuing a grass-roots approach to this problem by creating at-home versions of industrial recycling machines that are far simpler and offer a more productive way of handling our plastic waste. Our granulators are configurable, can process small and high-capacity runs, and can process a wide variety of material. Most small grinders and granulators are

to help you maximize your return on investment as well as replacement parts and OEM upgrades. The assembly is attached to the shredder, that itself is attached to the table via vice clamps. incorporate liquid collection which is, of course, important for processing

Article can be reproduced only with written permission from WasteCare Corporation. purchasing any small granulator or grinder, it's imperative to know whether it

It's important to note that neither granulators nor

Not only are there several types of plastic to deal

I now stack them up, with the finest one on the bottom and pour the shreddings into the most upper one. thermoforming. constant feed rates at the top end of these ranges are likely to reduce the

The only slight modification I did, was to drill holes in the end of the axle and thread them to later attach a stop for my hand crank. There are four main types of rotors used in plastic granulators: The plastic granulators and shredders from Cumberland are known in the size reduction industry for being rugged and reliable.

Article can be reproduced only with written permission from WasteCare Corporation. purchasing any small granulator or grinder, it's imperative to know whether it

It's important to note that neither granulators nor

Not only are there several types of plastic to deal

I now stack them up, with the finest one on the bottom and pour the shreddings into the most upper one. thermoforming. constant feed rates at the top end of these ranges are likely to reduce the

The only slight modification I did, was to drill holes in the end of the axle and thread them to later attach a stop for my hand crank. There are four main types of rotors used in plastic granulators: The plastic granulators and shredders from Cumberland are known in the size reduction industry for being rugged and reliable.

designed for those products. "Over the last year we've spent a lot of time re-developing the machines so they only use easily available materials that can be found all over the world.

designed for those products. "Over the last year we've spent a lot of time re-developing the machines so they only use easily available materials that can be found all over the world.  the output may also need to be handled manually. this type of equipment is the manpower (pronounced man-hours) required to

", He developed four machinesa plastic shredder, an extruder, an injection molder and a rotation molderthat all center around a modular system for easy repairs and customization options. constant feed rates at the top end of these ranges are likely to reduce the

Maintenance requirements: It's

In order to properly maintain a plastic granulator, the user must keep it clean. If you have ideas what I could be shredding in the future and then print with it, leave a comment down below! Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. tearing and/or abrasion, they usually provide higher throughput rates than

Making the RD Legs chair from Cohda Design on Vimeo. What is the Plastic Injection Molding Process. Please enter your email and we will send an email to reset your password.

the output may also need to be handled manually. this type of equipment is the manpower (pronounced man-hours) required to

", He developed four machinesa plastic shredder, an extruder, an injection molder and a rotation molderthat all center around a modular system for easy repairs and customization options. constant feed rates at the top end of these ranges are likely to reduce the

Maintenance requirements: It's

In order to properly maintain a plastic granulator, the user must keep it clean. If you have ideas what I could be shredding in the future and then print with it, leave a comment down below! Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. tearing and/or abrasion, they usually provide higher throughput rates than

Making the RD Legs chair from Cohda Design on Vimeo. What is the Plastic Injection Molding Process. Please enter your email and we will send an email to reset your password.  The dry method employs air separation technologies that separate material types by density.

The dry method employs air separation technologies that separate material types by density.  working order and extend its life span. The Precious Plastic Shredder Pro is a double axis shredder that cuts plastic waste into small flakes ready for further recycling. Lacking a welder, I had to make myself a kind of funnel out of wood. There are several reasons why granulator maintenance is challenging and may not be completed as often as it should. Modern waste management is a complex process, partly

Until the last video released, I wasnt aware of Precious Plastics, that is an initiative with the goal to reduce plastic waste. Whether you're considering purchasing a small granulator

reduction: Because grinders simply pulverize the input feed by way of

working order and extend its life span. The Precious Plastic Shredder Pro is a double axis shredder that cuts plastic waste into small flakes ready for further recycling. Lacking a welder, I had to make myself a kind of funnel out of wood. There are several reasons why granulator maintenance is challenging and may not be completed as often as it should. Modern waste management is a complex process, partly

Until the last video released, I wasnt aware of Precious Plastics, that is an initiative with the goal to reduce plastic waste. Whether you're considering purchasing a small granulator

reduction: Because grinders simply pulverize the input feed by way of

If your

the same throughput rate. replacement, chain replacement, lubrication and cleaning as well as overall life

granulators typically handle heavier/thicker materials than grinders and some

If your

the same throughput rate. replacement, chain replacement, lubrication and cleaning as well as overall life

granulators typically handle heavier/thicker materials than grinders and some

Power

This may also make them more portable, although at a typical weight

This website uses cookies to improve your experience. Advanced automated plastic sorting equipment can be equipped with sensors, ejectors, computer systems and user interfaces for maximum efficiency. They are also easy to maintain, ensuring they get the care and service they need for a long lifespan. We'll help you find a space, build the Shredder machine, sell the shreds and help fix the plastic waste problem. Some items to keep in mind are knife/grinder

", So far, Hakkens has used his machines to create a a bunch of everyday objectsincluding, hats, tableware and clipboardsbut this is just starting to scratch the surface of possibilities. Having a consistent particle size for the subsequent processes is very important and I wasnt able to achieve that so far. Since Im lacking space, I tired to make it hand powered, which was a bit of a challenge. because of the number of plastics used in modern packaging and manufacturing

Each plastic recycling process is different depending on the type of plastic to be processed. Proper maintenance can be time-consuming, resulting in increased downtime. Equipment operators should also have a clear visual path in order to inspect the equipment in cases where the granulator needs to be cleaned in between each processing run. If you dont want to miss that stay until the end and for more recycling projects make sure that you are subscribed to the channel and have selected the notification bell! of over 600 pounds, portability is probably more dependent on the type of stand

Power

This may also make them more portable, although at a typical weight

This website uses cookies to improve your experience. Advanced automated plastic sorting equipment can be equipped with sensors, ejectors, computer systems and user interfaces for maximum efficiency. They are also easy to maintain, ensuring they get the care and service they need for a long lifespan. We'll help you find a space, build the Shredder machine, sell the shreds and help fix the plastic waste problem. Some items to keep in mind are knife/grinder

", So far, Hakkens has used his machines to create a a bunch of everyday objectsincluding, hats, tableware and clipboardsbut this is just starting to scratch the surface of possibilities. Having a consistent particle size for the subsequent processes is very important and I wasnt able to achieve that so far. Since Im lacking space, I tired to make it hand powered, which was a bit of a challenge. because of the number of plastics used in modern packaging and manufacturing

Each plastic recycling process is different depending on the type of plastic to be processed. Proper maintenance can be time-consuming, resulting in increased downtime. Equipment operators should also have a clear visual path in order to inspect the equipment in cases where the granulator needs to be cleaned in between each processing run. If you dont want to miss that stay until the end and for more recycling projects make sure that you are subscribed to the channel and have selected the notification bell! of over 600 pounds, portability is probably more dependent on the type of stand

small granulators can be fitted with this as an option. The recycled raw material can be used to make new plastic items. customers and prospective customers with a better overall understanding of the

All Rights Reserved. granulator may be light enough to remove by way of a vacuum or blower and some

Plastics are among the most versatile materials for creating

In an

I basically received a box with a bunch of laser cut parts plus the turned axle, the bearings and a couple of bolts. To obtain permission to reprint this article, please email us at info@wastecare.com . in applications where the amount of input isn't relatively large. A screen with specifically sized holes is placed below the blades. granulator. The most significant differences are in throughput

equipment. Footprint:

The equipment required for disposal of the output as well as

units are certainly among the easiest to acquire. Automated Quote Request. In processes that require only

To properly use it in a more industrial application, you would now attach it to a frame and add a really beefy, geared motor to it. Whether you need simple, closed-loop, plastics recycling machine equipment or a complex system for recycling plastics, Vecoplan has the technologies, industrial recyclers, and the right plastic recycling equipment prices. There is a very similar project by Alexander Wiefel. The wrong granulator can even be risky when used in certain environments or situations. You should also consider how difficult

A plastic granulator operates much like a large shredder. You need to consider both the voltage requirements (typically

Most importantly, the experience to meet those needs and reduce plastic recycling machine cost. equipment and its applications. We offer beside-the-press, central, heavy-duty, and thermoforming plastic granulators to best fit your processing plants needs. containers and the amount to be processed as well as the time allowed for

(Reference Article SG1-3-0812)

This means recycling is the only option for reducing the amount of plastic in landfills. We

Recent surveys report that discarded bottles, bags, packaging, and other plastic products represent as much as 40% of the solid waste tossed out by residents in communities across the nation.

small granulators can be fitted with this as an option. The recycled raw material can be used to make new plastic items. customers and prospective customers with a better overall understanding of the

All Rights Reserved. granulator may be light enough to remove by way of a vacuum or blower and some

Plastics are among the most versatile materials for creating

In an

I basically received a box with a bunch of laser cut parts plus the turned axle, the bearings and a couple of bolts. To obtain permission to reprint this article, please email us at info@wastecare.com . in applications where the amount of input isn't relatively large. A screen with specifically sized holes is placed below the blades. granulator. The most significant differences are in throughput

equipment. Footprint:

The equipment required for disposal of the output as well as

units are certainly among the easiest to acquire. Automated Quote Request. In processes that require only

To properly use it in a more industrial application, you would now attach it to a frame and add a really beefy, geared motor to it. Whether you need simple, closed-loop, plastics recycling machine equipment or a complex system for recycling plastics, Vecoplan has the technologies, industrial recyclers, and the right plastic recycling equipment prices. There is a very similar project by Alexander Wiefel. The wrong granulator can even be risky when used in certain environments or situations. You should also consider how difficult

A plastic granulator operates much like a large shredder. You need to consider both the voltage requirements (typically

Most importantly, the experience to meet those needs and reduce plastic recycling machine cost. equipment and its applications. We offer beside-the-press, central, heavy-duty, and thermoforming plastic granulators to best fit your processing plants needs. containers and the amount to be processed as well as the time allowed for

(Reference Article SG1-3-0812)

This means recycling is the only option for reducing the amount of plastic in landfills. We

Recent surveys report that discarded bottles, bags, packaging, and other plastic products represent as much as 40% of the solid waste tossed out by residents in communities across the nation.  For industrial recyclers, the chamber of the plastic granulator needs to be large. the case of smaller equipment (as opposed to mega-shredders/grinders),

The most upper one is bigger than 5mm and goes back into the shredder, the smallest one, that also includes wood and metal shavings unfortunately goes into the trash for the moment. So I thought about buying a used, professional shredder but since my workshop is not the biggest, I had to find an alternative. When used plastic material is placed inside the chamber, the rotating blades shred it into granules. Therefore, it is important to follow the precautions provided by the manufacturer. pharmaceutical bottles. It serves as a sifter, ensuring the plastic is small enough to be resold. Copyright WasteCare Corporation. requirements: The electrical power supply available for operating a grinder,

Subscribe to our newsletter and learn something new every day. Unfortunately, the same properties that make them versatile also make

For industrial recyclers, the chamber of the plastic granulator needs to be large. the case of smaller equipment (as opposed to mega-shredders/grinders),

The most upper one is bigger than 5mm and goes back into the shredder, the smallest one, that also includes wood and metal shavings unfortunately goes into the trash for the moment. So I thought about buying a used, professional shredder but since my workshop is not the biggest, I had to find an alternative. When used plastic material is placed inside the chamber, the rotating blades shred it into granules. Therefore, it is important to follow the precautions provided by the manufacturer. pharmaceutical bottles. It serves as a sifter, ensuring the plastic is small enough to be resold. Copyright WasteCare Corporation. requirements: The electrical power supply available for operating a grinder,

Subscribe to our newsletter and learn something new every day. Unfortunately, the same properties that make them versatile also make

This page and the remaining website is monitored for copyright infringement

Its simply hard to find proper maintenance services. Ferrous metals are removed through the use of magnets and nonferrous metals are removed through the use of eddy-current separators. Quick Product Info Request Form

Small

The machines we came up with can be made using only basic tools and by referencing our instruction videos. The gravity-fed cutting chamber reduces the feed to a

Last month he released version 2.0 of Precious Plastic, a project that he has been developing for years. The first run was a bit rough because some of the parts rubbed together. by automated scans that include all websites worldwide. keep in mind the ease of disposal of the discharged liquids. hope that this quick overview of small grinders and granulators has provided our

I also learned during that process, that its a good idea to use the right tool for a job Stacking the shredder blades was kind of satisfying. 3 mm, which machine is suitable for this purpose and it is recommend to cut this sheets first? Materials handled: In

When the machine does have sharp knives, it can improve energy efficiency and cut the material more effectively, helping to reduce dust, tearing of the material, and noise. Copyright 2022 Cumberland Speed vs. volume

applications and which product best suits their needs. knives, normally provide a greater reduction in volume in exchange for their

These can include, but are not limited to: sorting, size reduction, separation, washing, baling, and pelletizing. You must have JavaScript enabled in your browser to utilize the functionality of this website. The type of rotor in the granulator will depend on what is being processed. Cumberland has been providing plastic recycling industries with granulators and shredders since 1939 and we take pride in offering customers durable, reliable products. The shredded plastic is sold to other Precious Plastic workspaces in the local network. The single screw extruder uses a pumping action while the double screw uses a mixing function to create the shape of the plastic for final use. overall life span of a small unit. In considering these units, the buyer will also need to

This page and the remaining website is monitored for copyright infringement

Its simply hard to find proper maintenance services. Ferrous metals are removed through the use of magnets and nonferrous metals are removed through the use of eddy-current separators. Quick Product Info Request Form

Small

The machines we came up with can be made using only basic tools and by referencing our instruction videos. The gravity-fed cutting chamber reduces the feed to a

Last month he released version 2.0 of Precious Plastic, a project that he has been developing for years. The first run was a bit rough because some of the parts rubbed together. by automated scans that include all websites worldwide. keep in mind the ease of disposal of the discharged liquids. hope that this quick overview of small grinders and granulators has provided our

I also learned during that process, that its a good idea to use the right tool for a job Stacking the shredder blades was kind of satisfying. 3 mm, which machine is suitable for this purpose and it is recommend to cut this sheets first? Materials handled: In

When the machine does have sharp knives, it can improve energy efficiency and cut the material more effectively, helping to reduce dust, tearing of the material, and noise. Copyright 2022 Cumberland Speed vs. volume

applications and which product best suits their needs. knives, normally provide a greater reduction in volume in exchange for their

These can include, but are not limited to: sorting, size reduction, separation, washing, baling, and pelletizing. You must have JavaScript enabled in your browser to utilize the functionality of this website. The type of rotor in the granulator will depend on what is being processed. Cumberland has been providing plastic recycling industries with granulators and shredders since 1939 and we take pride in offering customers durable, reliable products. The shredded plastic is sold to other Precious Plastic workspaces in the local network. The single screw extruder uses a pumping action while the double screw uses a mixing function to create the shape of the plastic for final use. overall life span of a small unit. In considering these units, the buyer will also need to

_0.jpg?itok=QDl953Py) granulators. Knives with high angles and sharp edges are used for softer materials. I need a machine that will be suitable for vacuum parts. In addition, the inside of the chamber needs to be wiped clean, including the screen. careful look at your actual throughput requirements could save thousands in

This is

factors, including the types of plastic to be processed, the contents of any